Neutralizers contain delicate ceramic honeycomb structures coated with precious metals like platinum and palladium. When someone asks where can I sell my catalytic converter after discovering damage, they often learn that physical testing reduced the component’s value significantly. Services like Autocatalyst help vehicle owners sell old emission control units to buyers who extract valuable metals, but damaged components fetch lower prices than intact ones.

The ceramic substrate inside these devices measures only a few millimeters thick in each cell wall. Even gentle tapping can create hairline fractures that aren’t immediately visible but compromise the unit’s effectiveness over time. These microscopic cracks allow unprocessed gases to bypass the treatment surfaces, reducing overall emission reduction efficiency.

Understanding Internal Component Vulnerability

The primary vulnerable elements include:

- Ceramic monolith substrate. The honeycomb structure consists of thin-walled ceramic cells that can crack under minimal impact force.

- Precious metal washcoat. Platinum, palladium, and rhodium coatings can flake off when subjected to vibration or shock.

- Mounting mat insulation. The fibrous material holding the ceramic core in place can compress or shift, creating loose components that rattle during operation.

These components work together in precise alignment, and any disruption affects the entire system’s performance.

Alternative Inspection Methods

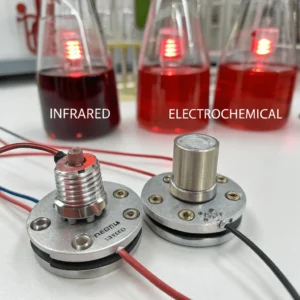

Professional technicians use several non-destructive testing approaches that provide accurate assessments without risking component damage. Visual inspection through inlet and outlet ports reveals obvious blockages or substrate damage without physical contact. Digital multimeters can test oxygen sensor readings to determine if the neutralizer processes gases effectively.

Temperature measurement offers another diagnostic approach. Mechanics use infrared thermometers to check temperature differences between inlet and outlet sides during operation. A properly functioning unit shows specific temperature patterns that indicate normal catalytic activity.

Modern diagnostic equipment provides the most reliable assessment methods:

- OBD-II scanners. These devices read error codes and monitor sensor data to identify emission system problems.

- Pressure testing. Specialized gauges measure backpressure to detect internal blockages or restrictions.

- Gas analyzers. Professional equipment measures actual emission levels to determine neutralizer efficiency.

These methods provide comprehensive information about system condition without risking expensive component damage.

Long-term Consequences of Improper Testing

Tapping damage often doesn’t manifest immediately, leading vehicle owners to believe the testing method caused no harm. Microscopic fractures expand over time due to thermal cycling and vibration during normal driving. What begins as a small crack eventually becomes a complete substrate failure that requires full replacement.

The financial impact extends beyond replacement costs. Damaged neutralizers lose significant resale value, and services like Autocatalyst pay substantially less for components with compromised substrates. Vehicle owners who used destructive testing methods often discover they’ve eliminated potential recovery value from their old emission control systems.